A forward-looking vision

Product and process innovation

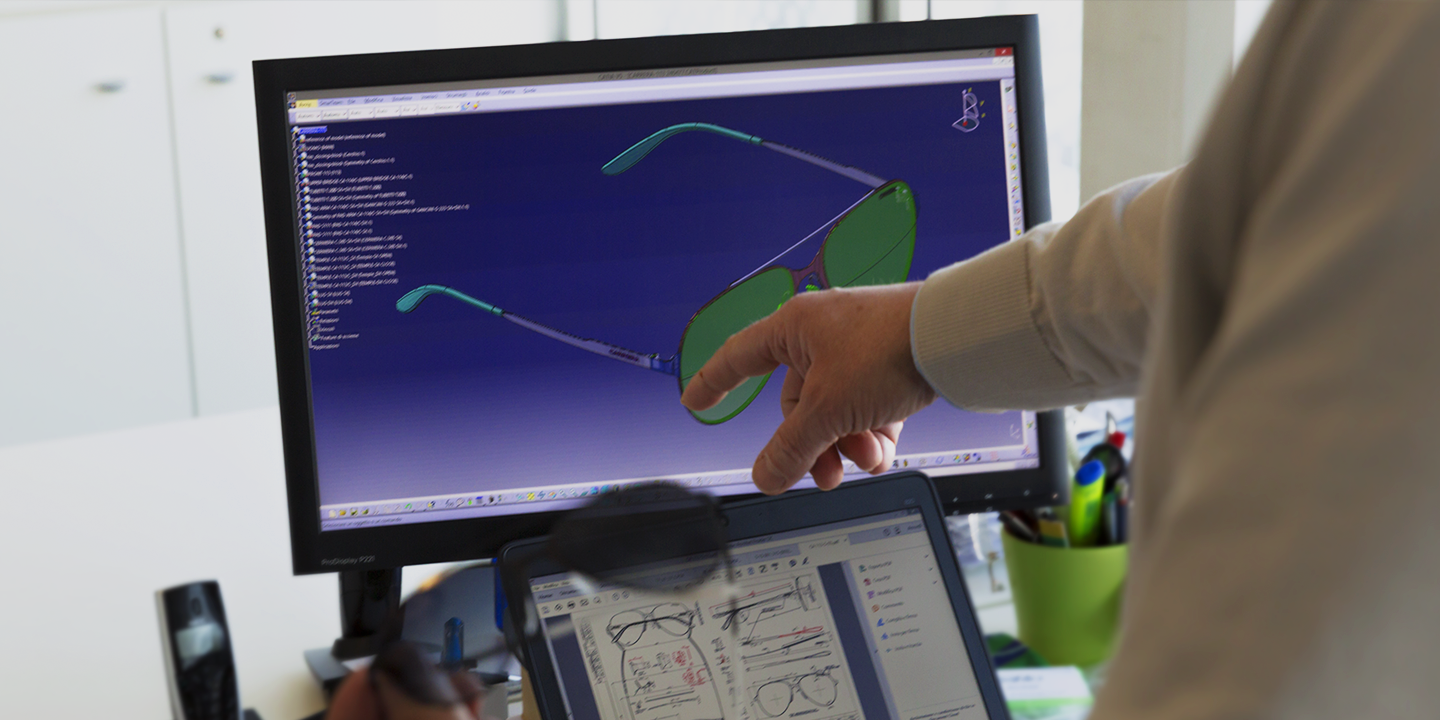

At our Global Innovation Centre, we analyse macro-trends, search for new materials and develop innovative technologies; here, through industrial engineering, specific solutions are tested to create high-quality products. We are committed to researching and developing new cutting-edge lens and frame solutions and treatments that help people improve their vision.

Our Product Certification Lab works with external certification organisations on new products and materials. In collaboration with universities, research centres, qualified suppliers, customers, industry experts and associations, we always search for innovative solutions.

Our priority is the quality of our products: our Corporate Lab plays a key role in making us a global leader in terms of quality and innovation thanks to the close collaboration with our research, innovation and product development departments.

Because we believe that ideas and skills, if shared, boost the innovation process:

We test the physiological compatibility of each pair of glasses: no risk of allergies

We test the fit and stability over time of each pair of glasses: comfort as a mission

We test the optical quality and strength of the lenses in each pair of glasses: the pleasure of seeing properly.

Materials

We promote sustainable solutions and the use of green materials such as recyclable and bio-based polymers to make high-quality products that protect people’s eyesight while reducing the use of new resources. Thanks to a pioneering partnership with Aquafil, we have introduced a unique plastic material, ECONYL® regenerated nylon, never before used in industrial eyewear production. This is one of the tangible signs of our commitment to sustainability strategies. We use bio-based plastics, i.e. plastics partially derived from renewable resources such as castor oil - resulting in less dependence on petroleum - and materials with a low content of environmentally harmful chemicals.

Digital

At our Italian production sites, Industry 4.0 projects are up and running in collaboration with two start-ups: Azzurro Digitale, which has supported us in digitalising factory reporting and quality management; and I Consulting for the digitalisation of planning, logistics and reporting.

Digital Transformation

We regularly invest in and launch digital initiatives and projects, since this is one of the key objectives of our Group Business Plan 2020-2024.

Our sustainable supply chain

We carefully select our suppliers, assessing their environmental and social choices, with the aim of ensuring reliability and sustainability throughout the supply chain. The Corporate Responsible Sourcing Supplier Manual allows us to manage our suppliers and industrial partners responsibly, making sure that they comply with international standards, share Safilo’s values and promote the application of high standards. Regular supplier audits allow us to check their certifications and their ability to reduce their environmental impact.

Figures

Supplier assessment and selection process

In order to assess our suppliers, we have adopted the Self-Assessment Questionnaire (SAQ), which provides us with a comprehensive overview on the important topics of labour law, human rights, health and safety, environmental responsibility, anti-corruption, safety and quality of goods and services.